Before we try to explain the differences between a SOHC (Single Overhead Camshaft) and DOHC (Dual Overhead Camshaft) setup, for the uninitiated’s sake, let’s try to understand what the duties of a Camshaft are. Inside an internal combustion engine (whether it is air cooled, oil cooled or liquid cooled), a Camshaft is a rotating cylindrical rod with a number of oblong lobes which protrude from it. With every rotation, the differently positioned lobes first push the intake valve(s) to allow air inside the cylinder to mix with fuel and combust, and then the exhaust valve(s) for the resultant gases to escape. In modern motorcycle engines, valve springs provide the return force for the valves to pull back to their shut position once the lobe rotates away.

Know More

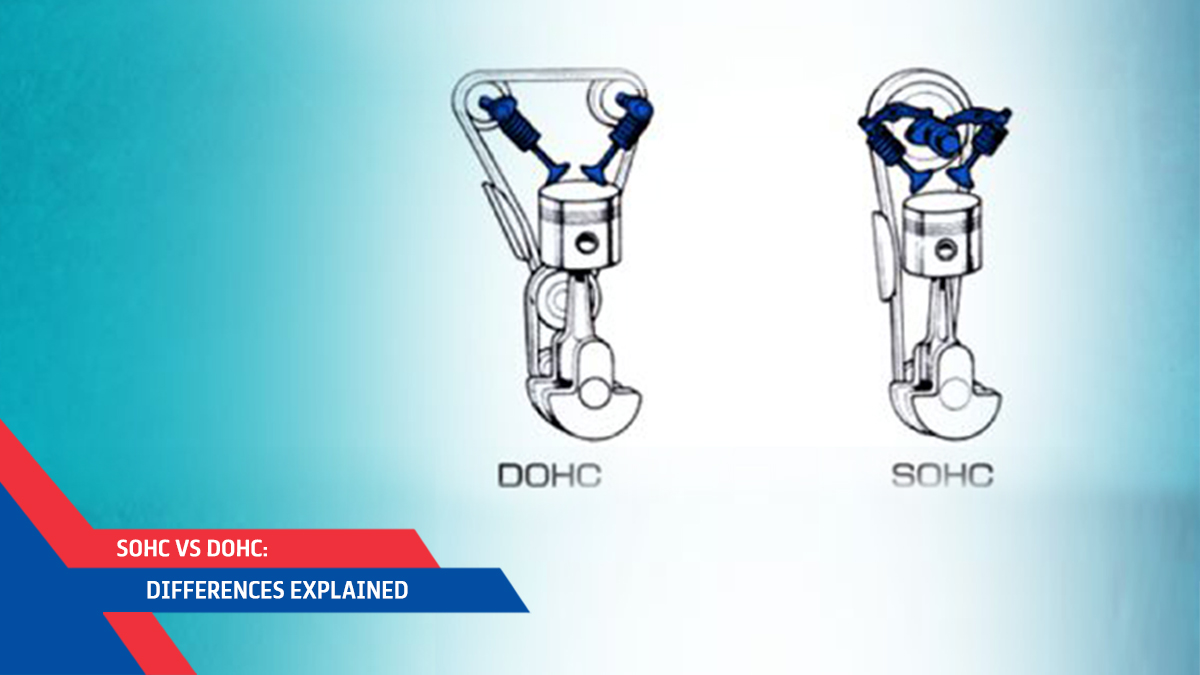

When a single camshaft governs both intake and exhaust valves, the setup is commonly known as SOHC. On the other hand, when there are two dedicated camshafts, one to push the inlet valves and the other to push the ones which let the gases escape from the cylinder after combustion the setup is called DOHC. In both instances, the camshaft is positioned above the valves for more accurate actuation.

There’s also another setup called OHV (Over Head Valve) which is traditional, less efficient than the other two and is rarely adopted these days. In an OHV design, the camshaft is installed inside the engine block and valves are operated by lifters, pushrods and rocker arms. For this very reason, an OHV engine is also known as a “pushrod” engine. The main disadvantage of an OHV design is that it’s difficult to precisely control the valve timing at high rpm because of the higher inertia caused by a larger amount of valve train components. This makes an OHV design better suited for engines with large volume which offer higher torque at lower RPMs. With the basics out of the way, let us now understand what are the advantages and disadvantages of employing a SOHC or a DOHC setup.

Single overhead cam setup

A SOHC setup typically allows a 2 or 3 valves per cylinder configuration, where usually, one valve allows air to enter and the other allows gases to escape. However, a manufacturer’s engineering prowess can also allow 4 valves per cylinder configuration using SOHC. Such a setup allows for more airflow than 2 valves per cylinder, as there is a larger open area for the air to enter the cylinder and gases to escape when the valves are open. Example: The TVS Apache RTR 200 4V.

Because the mass of the valvetrain is lesser in such a configuration, a SOHC 4 valve engine would have better torque towards the low end. In comparison, because of the higher mass of the valvetrain, a DOHC configuration will produce lower amounts of torque initially with as many valves but the top-end performance will be better. The other advantage of two valves per cylinder setup is the reduction of parts, which saves cost and complexity. The design also tends to be better for low and mid-range torque as the airflow is faster at these engine speeds as a result of a more restricted flow. However, a SOHC setup means that the Camshaft is usually placed in the middle of the head which denies the spark plug its ideal location.

Dual overhead cam setup

DOHC was introduced to improve the volumetric efficiency of an internal combustion engine, the result of which is more powerful. With this design, camshafts can be installed further apart from each other. This allows the intake valves to be at a larger angle from the exhaust valves, which results in a more direct airflow through the engine with less obstruction. In other words, a DOHC engine can breathe better and thus produce more horsepower out of smaller engine displacement. Also, it is easier to implement efficiency-enhancing technologies like Variable Valve Timing in a DOHC engine.

A DOHC setup allows easy implementation of a 4 valve per cylinder configuration. Most of the times, it allows the engine to rev higher. It also allows for the valves to be placed in an optimized setup for maximum performance. A DOHC, four valves per cylinder configuration allows better airflow at high engine speeds, resulting in better top end power. DOHC engines also allow the spark plug to be placed right in the middle of the combustion chamber which in turn promotes efficient combustion. The disadvantage of such a setup is more weight, higher costs and also the fact that driving two camshafts requires more components.

To sum it up, a 4 Valve per cylinder SOHC engine with a lighter valvetrain mass would have better performance characteristics at the lower end of the powerband. However, at higher engine speeds, a DOHC setup with its higher valvetrain mass and as many valves per cylinder will develop higher peak torque and horsepower. You can also check out our extensive blog on disc brakes for deeper insights.

Comments (171)

1xcasinoDiory

06 May 2021

RobertChade

06 May 2021

casinoapksAcino

07 May 2021

casino-x

07 May 2021

CasinoX

07 May 2021

CasinoX

08 May 2021

forexinvesthap

08 May 2021

TerryMit

09 May 2021

1xbetchirm

09 May 2021

Pin-up_urict

09 May 2021

smartheigo

09 May 2021

vavadaTup

10 May 2021

zarabotat_loM

10 May 2021

Zaimdog

10 May 2021

vavadaTup

12 May 2021

1win_rostov_launc

12 May 2021

1win_ekbPruts

13 May 2021

1win_izhevsk_Shoro

13 May 2021

1win_Kazan_dresy

15 May 2021

Francisrof

16 May 2021

1win_msk_lok

16 May 2021

1win_nn_Glync

17 May 2021

1win_nn_Glync

18 May 2021

1win_spb_blelf

18 May 2021

1win_samara_muT

19 May 2021

1win

19 May 2021

1xbetheigo

19 May 2021

1xcasinoDiory

20 May 2021

1win_nsk_bok

21 May 2021

1win_spb_blelf

21 May 2021

1win_samara_muT

22 May 2021

1win_nsk_bok

23 May 2021

1win_nsk_bok

23 May 2021

1win_spb_blelf

23 May 2021

1win_samara_muT

24 May 2021

1win_nsk_bok

25 May 2021

1win_spb_blelf

25 May 2021

1win_samara_muT

26 May 2021

1win

29 May 2021

1xcasinoDiory

31 May 2021

RobertChade

01 Jun 2021

casino-x

02 Jun 2021

CasinoX

03 Jun 2021

forexinvesthap

04 Jun 2021

TerryMit

05 Jun 2021

Belio

05 Jun 2021

1win_rostov_launc

06 Jun 2021

smartheigo

06 Jun 2021

Zaimdog

07 Jun 2021

vavadaTup

07 Jun 2021

1win_ekbPruts

08 Jun 2021

1win_izhevsk_Shoro

08 Jun 2021

1win_Kazan_dresy

09 Jun 2021

Francisrof

09 Jun 2021

1win_msk_lok

10 Jun 2021

1win_nn_Glync

11 Jun 2021

1win_nsk_bok

11 Jun 2021

1win_spb_blelf

12 Jun 2021

1win_samara_muT

12 Jun 2021

1win

12 Jun 2021

LEINBERGER2197

13 Jun 2021

TOASTON8197

14 Jun 2021

MENCHU5534

14 Jun 2021

SUE2986

14 Jun 2021

BELLUOMINI0241

14 Jun 2021

SCHOFIELD5360

15 Jun 2021

1xbetheigo

15 Jun 2021

1xcasinoDiory

15 Jun 2021

1xcasinoDiory

16 Jun 2021

RobertChade

16 Jun 2021

casino-x

16 Jun 2021

CasinoX

17 Jun 2021

vavadaTup

17 Jun 2021

forexinvesthap

18 Jun 2021

TerryMit

18 Jun 2021

Dzhinsa

18 Jun 2021

1win_rostov_launc

19 Jun 2021

smartheigo

19 Jun 2021

vavadaTup

19 Jun 2021

1win_ekbPruts

19 Jun 2021

1win_izhevsk_Shoro

19 Jun 2021

1win_Kazan_dresy

20 Jun 2021

Francisrof

20 Jun 2021

1win_msk_lok

20 Jun 2021

1win_nn_Glync

20 Jun 2021

1win_nsk_bok

20 Jun 2021

1win_spb_blelf

21 Jun 2021

1win_samara_muT

21 Jun 2021

1win

21 Jun 2021

1xbetheigo

22 Jun 2021

1xcasinoDiory

22 Jun 2021

RobertChade

22 Jun 2021

casino-x

23 Jun 2021

CasinoX

23 Jun 2021

vavadaTup

23 Jun 2021

forexinvesthap

23 Jun 2021

TerryMit

24 Jun 2021

1win_rostov_launc

24 Jun 2021

smartheigo

24 Jun 2021

Zaimdog

25 Jun 2021

vavadaTup

25 Jun 2021

1win_ekbPruts

26 Jun 2021

1win_izhevsk_Shoro

26 Jun 2021

1win_Kazan_dresy

26 Jun 2021

Francisrof

26 Jun 2021

1win_msk_lok

27 Jun 2021

1win_nn_Glync

27 Jun 2021

1win_nsk_bok

27 Jun 2021

1win_spb_blelf

27 Jun 2021

1win_samara_muT

27 Jun 2021

casinoapksAcino

27 Jun 2021

1win

28 Jun 2021

1win

28 Jun 2021

1win

30 Jun 2021

1Win_staks

01 Jul 2021

1xbet1xRurce

02 Jul 2021

1xbet1x_Preek

03 Jul 2021

1xbet_Mex

03 Jul 2021

1xbet_seSia

03 Jul 2021

1xcasinoDiory

04 Jul 2021

RobertChade

04 Jul 2021

casinoapksAcino

05 Jul 2021

casino-x

06 Jul 2021

CasinoX

06 Jul 2021

forexinvesthap

07 Jul 2021

TerryMit

07 Jul 2021

smartheigo

08 Jul 2021

Zaimdog

08 Jul 2021

vavadaTup

09 Jul 2021

StephenOpile

09 Jul 2021

1xslot_lials

09 Jul 2021

DavidMon

10 Jul 2021

1win_Dieta

10 Jul 2021

binance_Axors

10 Jul 2021

1win

11 Jul 2021

1Win_staks

11 Jul 2021

1xbet1xRurce

11 Jul 2021

1xbet1x_Preek

11 Jul 2021

1xbet_Mex

12 Jul 2021

1xbet_seSia

12 Jul 2021

1xcasinoDiory

12 Jul 2021

RobertChade

12 Jul 2021

casinoapksAcino

13 Jul 2021

casino-x

13 Jul 2021

CasinoX

13 Jul 2021

forexinvesthap

14 Jul 2021

Vineethraj

22 Jan 2022

8129459611

tcsgroupi

13 Apr 2022

selamectin (trade names, revolt manufactured by aurora pharmaceutical & revolution manufactured by zoetis ) is a topical parasiticide and anthelminthic used on dogs and cats. it treats and prevents infections of heartworms, fleas, ear mites, sarcoptic mange (scabies), and certain types of ticks in d

Juan

22 Jun 2022

What can I do to make more performances to my 3.6 l engine

Houbs

14 Jul 2022

Thomasrax

25 Jan 2023

https://heating-film.com/

Mahesh

28 Jan 2023

Bad

BrentDaf

30 May 2023

https://pq.hosting/ro/vps-vds-austria-wien

Abu Ayman

06 Jun 2023

I'm very interested in the modern technology tvs implementing on their vehicles. Dohc inverted engine in rr310. I'm very passionate about knowing more about tvs vehicles through industrial experience. Are providing any internship training opportunities for ignited minds like me.looking forward to mo

Riene

17 Jun 2023

Thank you so much. Your post is very informative. Kodus for sharing this technical knowledge.

jHqhTgN

17 Jul 2023

IoAhUHqN

21 Nov 2023

aSAqfeshiD

BECTcAgbPRv

21 Nov 2023

yOidQnrR

fNkKDAwv

23 Nov 2023

AHwxWvUlYzjDBhb

WYpOCndfVmEhKkx

23 Nov 2023

nrlDIdhEvLjzXk

Danielaej

28 Nov 2023

I really like cycling, I not too long ago purchased an electric bike and it means I can now journey for miles and discover the villages native to me. Gone are the times when individuals used to publish matrimonial ads in newspapers and magazines or they had to visit local matchmaking agencies so as

AlvinJak

06 Dec 2023

https://www.adulthubtube.com/

Jamessauro

07 Dec 2023

https://www.threexvideo.com/

EllisCyhob

08 Dec 2023

https://www.madhousedc.com/

MarvinGlive

08 Dec 2023

https://www.daylyporn.com/

avenue17

19 Dec 2023

There is a site on a theme interesting you.

Davidtheah

24 Jan 2024

Unlock the world with our affordable, high-quality proxies from various countries! Get instant access to global content, enhance your internet privacy, and enjoy seamless browsing. Plus, use the promo code "AxitPHiWiM" at checkout for an exclusive 5% discount. Don't miss this chance to elevate your

Sudhir Kumar

30 Jan 2024

Coupon for wallet

yes sir

19 Mar 2024

ily pookie bear

Williezef

09 Apr 2024

https://list.ly/carrentalhawaiicom/lists

SIKHA VINOD KUMAR

10 Apr 2024

Good Explanation